How to Prevent Look-Alike Packaging Confusion in the Pharmacy

Dec, 8 2025

Dec, 8 2025

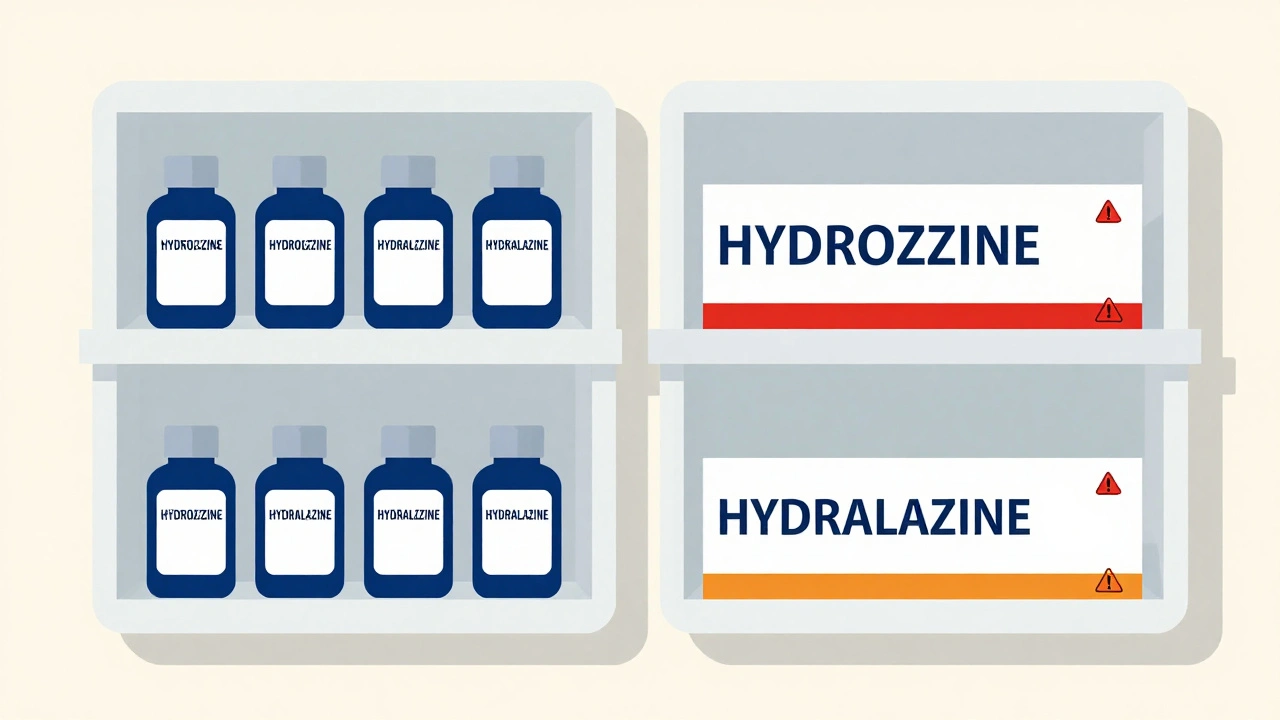

Every year, thousands of patients in the U.S. receive the wrong medication-not because of a doctor’s mistake, but because two pills look too much alike on the shelf. One bottle might say hydralazine, another hydroxyzine. One label says spironolactone, another spiramycin. To the untrained eye, they’re nearly identical. And in a busy pharmacy, under pressure, that’s all it takes for a deadly mix-up.

According to the Institute for Safe Medication Practices (ISMP), about 18% of all medication error reports in the U.S. come from look-alike packaging or similar drug names. That’s roughly 10,000 preventable mistakes each year. Some lead to hospitalizations. Others result in death. The good news? These errors aren’t inevitable. With the right strategies, pharmacies can cut these mistakes by more than 90%.

Why Look-Alike Packaging Is So Dangerous

It’s not just about names. It’s about the whole package: bottle shape, label color, font size, logo placement. Two drugs can have completely different uses-one treats high blood pressure, the other an allergic reaction-but if they’re packaged the same way, a pharmacist grabbing the wrong one is easy. And it’s not just human error. Automated systems can misread labels if the text isn’t clear. Even barcode scanners fail if the label design confuses the scanner.

Look-alike errors spike during high-stress times: shift changes, drug shortages, or when a new medication is added to inventory. A 2023 study from the University of Arizona found that when similar-looking drugs were stored next to each other, error rates jumped by 62%. That’s why simply telling staff to “be more careful” doesn’t work. You need systems that make mistakes harder to make.

Physical Separation: The Simplest Fix

One of the most effective-and cheapest-ways to prevent look-alike errors is to physically separate similar drugs. Put them on different shelves. Use colored dividers. Assign them to different drawers in automated dispensing cabinets. You don’t need fancy tech. Just space and intention.

A hospital in Arizona moved all insulin types into their own dedicated section, separated by type (long-acting, rapid-acting). Within 18 months, wrong-insulin errors dropped from 3-4 per month to zero. Another pharmacy separated heparin and saline solutions-two drugs that look nearly identical in small vials-and eliminated all related errors in a year.

Cost? As low as $200 for plastic shelf dividers. No software. No training. Just rearranging what’s already there. The catch? It only works if the pharmacy layout allows it. In small community pharmacies with tight storage, this can be tough. But even then, using colored tape or labeled bins can create visual separation.

Tall Man Lettering: Making Names Impossible to Miss

When two drug names are almost the same, changing how they’re written can make all the difference. That’s Tall Man Lettering. It uses uppercase letters to highlight the parts of the name that differ.

Instead of hydroxyzine and hydralazine, you write HYDROXYZINE and HYDRALAZINE. The difference jumps out. Studies show this cuts selection errors by 47%. The FDA and ISMP both recommend it for high-risk pairs like DOPamine vs. DoBUTamine, or CLONidine vs. CLONIDINE.

But here’s the problem: not everyone uses it the same way. A 2022 survey found only 68% of hospitals use standardized Tall Man Lettering. Some systems capitalize the last few letters. Others the middle. If your EHR system shows clonidine while the pharmacy label shows CLONIDINE, confusion grows.

Fix it by standardizing across your system. Work with your EHR vendor to enforce consistent Tall Man Lettering for all high-risk pairs listed in ISMP’s quarterly updated list. Add it to your pharmacy’s internal checklist. Make it non-negotiable.

Barcode Scanning: The Safety Net That Works

Barcode scanning is the most powerful tool in the toolbox. When a pharmacist scans a medication before dispensing, and the system checks it against the prescription, errors drop by 86%. That’s not a guess. It’s backed by the Agency for Healthcare Research and Quality (AHRQ).

At Mayo Clinic, combining barcode scanning with physical separation of look-alike drugs eliminated 100% of potential errors over a 12-month period. The system flags mismatches instantly: “This is morphine, but the order is for hydromorphone.”

The downside? Cost. Full implementation runs $15,000 to $50,000 per pharmacy. Staff might skip scanning if they’re rushed. A 2021 study from UCSF found that 5-12% of scans were bypassed during peak hours.

Solution? Don’t rely on scanning alone. Use it as a backup. Train staff that scanning isn’t optional-it’s the last line of defense. Make it part of your culture. Reward compliance. Audit scans weekly. And always pair it with physical separation and clear labeling.

Labeling and Alert Systems: Small Changes, Big Impact

Even without new tech, you can make labels work harder. Add bright, bold warning stickers to look-alike drugs. Use red or yellow labels for high-risk pairs. Write “DOUBLE-CHECK” across the label. Put a small icon next to it-a warning triangle, a pair of eyes.

A retail pharmacy in Texas started using custom alert labels for spironolactone and spiramycin. Within months, wrong-drug dispensing dropped by 75%. But staff stopped using them during busy times. So they added the label check to their daily quality assurance routine. Compliance went back up.

Also, don’t forget the packaging. If a new drug arrives that looks like one you already carry, pause. Don’t just put it on the shelf. Compare the shape, color, font, size. If it’s too similar, flag it. Ask your supplier for a different package. Or request a change in labeling.

Training and Culture: The Human Element

Technology helps. But people prevent errors. Staff need to know which drugs are risky. They need to know how to use the tools. And they need to feel safe speaking up when something looks wrong.

Run monthly 15-minute safety huddles. Highlight one look-alike pair. Show a real case. Ask: “What would you do if this came in tomorrow?”

Use ISMP’s free Tool for Evaluating the Risk of Confusion Between Drug Names. It takes 8-12 hours to run for a typical pharmacy. But it tells you exactly which drugs are most likely to be mixed up in your setting.

And don’t punish mistakes. Build a reporting culture. If a pharmacist catches a near-miss, thank them. Celebrate it. That’s how you turn fear into vigilance.

What the Future Holds

The FDA is pushing harder than ever. In February 2024, they released draft rules requiring standardized Tall Man Lettering for 25 new high-risk drug pairs. ISMP added 17 more confusing pairs to their list in January 2024, including buprenorphine and butorphanol.

Soon, AI will help too. Pilot programs at Johns Hopkins use machine learning to scan drug images and flag packaging similarities before they even hit the shelf. The system spots mismatches in font size, color contrast, or logo placement-things humans miss.

By 2030, experts predict 95% of pharmacies will have layered prevention systems in place. The question isn’t whether you’ll adopt these strategies. It’s whether you’ll wait until someone gets hurt.

Start Here: Your 30-Day Action Plan

- Download ISMP’s 2024 List of Confused Drug Names. Highlight the ones you carry.

- Walk your pharmacy. Find any look-alike drugs stored next to each other. Move them apart.

- Apply Tall Man Lettering to all high-risk names in your EHR and printed labels.

- Add alert stickers to those drugs-red, bold, visible.

- Run a 10-minute staff training on one pair. Ask them to find three similar drugs in your inventory.

- Check your barcode scanner logs. If bypass rates are above 5%, investigate why.

You don’t need a big budget. You don’t need to wait for new tech. You just need to act. Because every time you fix one look-alike pair, you save a life.

Taya Rtichsheva

December 8, 2025 AT 20:00so like... we pay pharmacists to read and yet we make the labels look like a game of spot the difference in a toddler's coloring book? lol

Evelyn Pastrana

December 10, 2025 AT 10:15i work at a small clinic and we started using colored tape on high-risk meds. no fancy tech. just red tape on hydralazine and blue on hydroxyzine. errors dropped to zero. people think it's silly but i'd rather look silly than bury someone

Nikhil Pattni

December 11, 2025 AT 11:13you guys are missing the real issue. it's not the labels or the shelves. it's the fact that pharmacists are overworked and underpaid. in india we have 1 pharmacist for every 3,000 people. here in the US you're lucky if you get 1 per 1,500. nobody can focus when they're doing 120 scripts an hour. fix the staffing crisis first. all this tall man lettering and barcode scanning is just band-aids on a hemorrhage. also i use emojis to cope: 🥲💉

Elliot Barrett

December 13, 2025 AT 01:19why are we even talking about this? it's not rocket science. if you can't read a label, don't work in a pharmacy. people need to stop making excuses and just pay attention. also barcode scanners are expensive. we don't need them. just train your staff better. #americanmediocrity

Andrea Beilstein

December 13, 2025 AT 14:15we treat medicine like a commodity but it's not. it's a sacred trust. when a bottle looks like another... it's not a design flaw. it's a moral failure. we've normalized risk because we're too busy optimizing profit margins to care about the human on the other end of the pill. i'm not mad. i'm just... deeply sad

Sabrina Thurn

December 13, 2025 AT 20:59the ISMP's 2024 high-risk list is essential. we implemented their recommended tall man lettering for 12 pairs last quarter. our error rate dropped from 0.8% to 0.04%. barcode scanning alone isn't enough - it's the layered approach: separation + labeling + scanning + culture. also, audit logs show that 92% of bypasses happen during 3–5 PM shifts. schedule breaks better. staff fatigue is the silent killer here

Richard Eite

December 15, 2025 AT 15:15USA is the only country that needs 7 different systems to stop people from dying from bad handwriting. fix the damn labels. stop wasting money on tech. just make the names look different. problem solved. #americanwastefulness

Tim Tinh

December 16, 2025 AT 13:29my aunt got the wrong med last year. she’s fine now but man... that was scary. we switched to the red sticker thing and it actually helped. staff still forget sometimes but now we all check each other. it’s like a little safety dance. also typo on my phone so sorry if i misspelled anything 🙏

Stacy Tolbert

December 17, 2025 AT 12:46i just lost my mom to a mix-up like this. hydralazine vs hydroxyzine. they said it was an 'error' like it was an accident. it wasn't. it was neglect. they knew the drugs looked alike. they didn't move them. they didn't label them. they didn't care. now i have to live with that. so please. just do something. anything.

Ryan Brady

December 18, 2025 AT 20:42barcodes? really? we're gonna spend 50k on scanners when we could just teach people to read? 🤦♂️ #americanoverengineering #makepharmacygreatagain

Raja Herbal

December 20, 2025 AT 02:30in india we don't have fancy shelves or scanners. we have memory. we memorize the look of the bottle, the feel of the cap, the sound it makes when you open it. sometimes that's more reliable than a barcode. but yeah... we also have 10x the workload. so it's not a model to copy. just saying - humans adapt. even without tech.

Iris Carmen

December 21, 2025 AT 10:43so like... the whole thing is just a giant game of 'which one is not like the other' but the stakes are someone's life? yeah. that's wild. also i think someone should make a meme about this. it's too real

Delaine Kiara

December 21, 2025 AT 18:34you know what's worse than look-alike drugs? when the pharmacy manager says 'we don't have budget for that' while they're driving a new Tesla. i've seen it. i've seen the budget for the holiday party. i've seen the budget for the fancy new coffee machine. but no money for red stickers? come on. this isn't about money. it's about priorities. and yours are messed up

Lauren Dare

December 22, 2025 AT 15:00the real bottleneck isn’t the tech or the training - it’s the EHR vendor lock-in. most systems don’t support dynamic tall man lettering enforcement. you need to push your vendor. demand it in the contract. if they won’t comply, switch. this isn’t a 'nice-to-have' - it’s a compliance and liability imperative. and if your compliance officer doesn’t get that, they’re not doing their job